Mokhanni oa daphragm tobetsa ka With Belt Combol bakeng sa kalafo ea lipalesa tsa metsi a senya

Lihlahisoa tsa sehlahisoa

Sesebelisoa sa daiphragm tobetsa lisebelisoa tse tšoanang: Mochini oa Belt, metsi

A-1. Khatello ea ho fifala: 0.8Ma; 1.0La; 1.3La; 1.6La. (Ea boikhethelo)

A-2. Khatello ea Diaphragm e pepesa khatello ea likulo: 1.0mpa; 1.3La; 1.6La. (Ea boikhethelo)

B, mocheso oa ho fifala: 45 ℃ / mocheso oa kamore; 65-85 ℃ / mocheso o phahameng. (O ka ikhethela)

C-1. Mokhoa oa ho lahla mokhoa oa ho phalla - ho phalla hantle: ho beoa ka tlase ho mahlakore a leqele le le letona la poleiti ka 'ngoe, le siling e tsamaeang. Phallo e bulehileng e sebelisoa bakeng sa lino tse sa hlakoloeng.

C-2. Mokokotlo oa metsi o hahlaula o pharalletse Haeba mokelikeli o hloka ho fumanoa, kapa haeba mokelikeli o sa fetohe, o tukang, o tukang o phatlohang, o phatloha, o sebelisoa.

D-1. Khetho ea lingoliloeng tsa lesela la filthara: PH ea mokelikeli e nka qeto ea thepa ea filter. PH1-5 ke masela a sefahleho sa polyester oa acid, PH8-14 ke alkaline lesela la filystene polypropingne. Mokelikeli oa Viscous kapa o tiile o khethoa ho khetha lesela la filthara, le mokelikeli oa li-viscous kapa o tiileng o khethiloeng oa litšoantšo.

D-2. Khetho ea clog ea filter mesh: Mokelikeli o arotsoe, 'me nomoro e lekanang ea mesh e hlophisitsoe bakeng sa boholo bo fapaneng. Filter Cloth Mesh Range 100-1000 Mesh. Micron to Mesh Regord (1um = 15,000 Meshi ea 15,000.

Phekolo ea E.Rrack " Bokaholimo ba mochine oa khatiso oa Filter ke lehlabatheng la pele, ebe baa fafatsoa ka pente ea primer le e thibelang limela. Boleng ba PH ke alkaline ea motlakase e matla, bokaholimo ba Mochine oa "Filter" ke sa lehlabathe, bo fafalitsoeng ka primer, 'me bokaholimo bo koahetsoe ke tšepe e se nang mabele kapa ea PP.

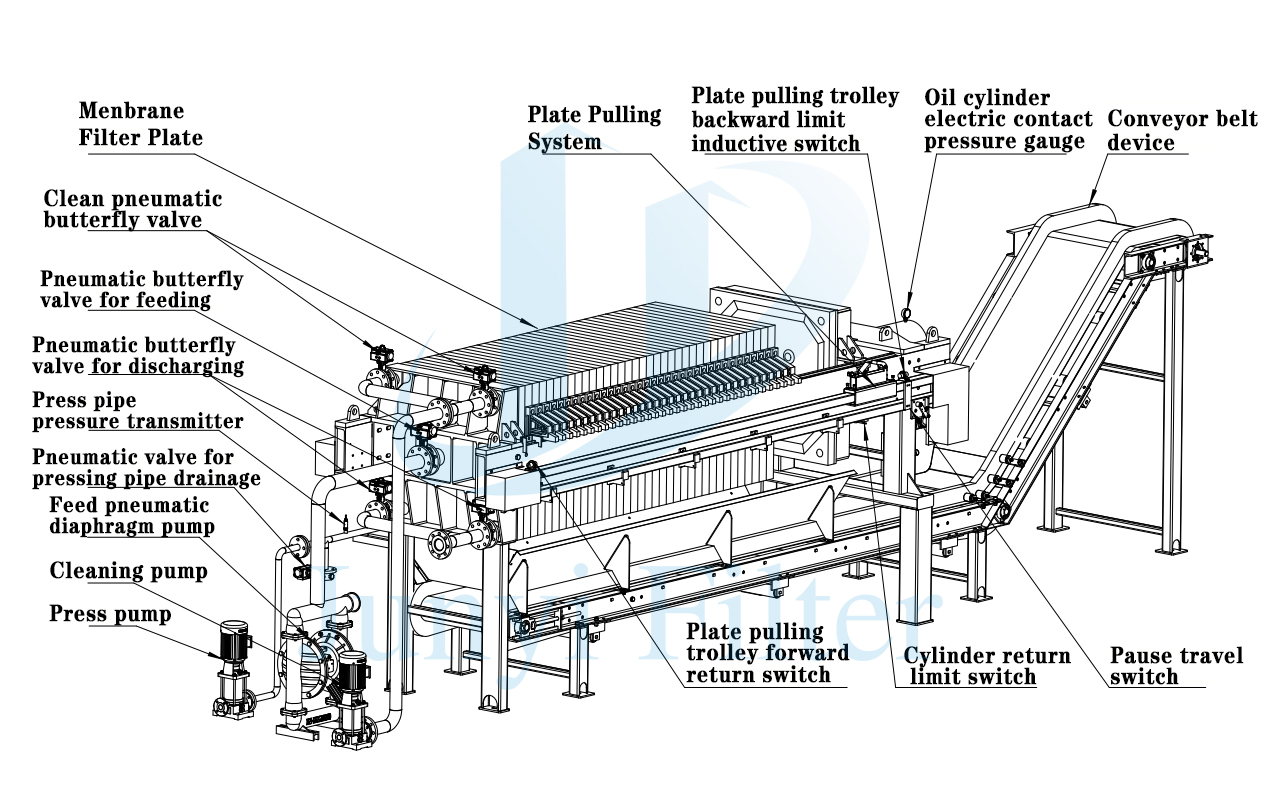

Ts'ebetso ea FER.DIAPHRAGM PROPAN PORTORT: Outchic handraulic ha ho na khatello ea maikutlo; Celter Cake Washing, Sefate sa "sephatlalatsi sa Boithati; TLATPILE PLATE PLAT PLAKENG KHOTSO A QETELA; Sisteme ea sefahleho ea veter e ikemetseng. Ke kopa o mpolelle mesebetsi eo o e hlokang pele o odara.

Keke ea ho hlatsoa: Ha li-soids li hloka ho fumanoa, kuku ea makhasi e acidic kapa alkaline; Ha kuku ea filthara e hloka ho hlatsuoa ka metsi, ka kopo romella lengolo-tsoibila ho botsa ka mokhoa oa ho hlatsoa.

H.ifter tobetsa ho fepa pompo ea pompo: tekanyo e tiileng, mocheso le litšobotsi tse fapaneng tse fapaneng lia hlokahala. Ka kopo romella lengolo-tsoibila ho botsa.

I.Automaticatic Belt Convyor: Khokahano ea Belt e kentsoeng tlasa poleiti ea sefako Sesebelisoa sena se loketse morero o sa tšoaneleheng ho etsa fatše. E ka tlisa kuku sebakeng se khethiloeng, se tla fokotsa mosebetsi o boima oa basebetsi.

J.automatic o otsellera o rerang Nakong ea lipalesa, litšepe tse peli tsa lipole li sebakeng se koetsoeng, se ka etelletsang metsi a thellang nakong ea firfice le lesela le hlatsoang metsi tseleng ea metsi. Kamora ho hloka fono, literata tse peli tsa lipole li tla buloa ho tlosa kuku.

K.The Filter Tobetsa Sistiming ea metsi e felisang metsi: E kentsoe kaholimo ho ts'ebetso ea mantlha, 'me lesela la filthara le metsi a nang le khatello ea kelello (36.0FA) ka ho fetola valve. Ho na le mefuta e 'meli ea meaho ea ho kuta: ho kuta ka tsela e fokolang, ho hlatsoa habeli Ka mochine o fofang, metsi a hlabang a ka sebelisoa hape hape a le ho sebelisoa hape ka kalafo ho boloka lisebelisoa; Kopanoa le sistimi ea diaphragm, e ka fumana litaba tse tlase tsa metsi; Kopana le sebopeho, sebopeho se kopanenlletseng, ho bonolo ho khesa le ho tsamaisa.

| Filter Prithis Fa Mohlala | |||||

| Lebitso la metsi | Karolelano ea metsi a tiileng(%) | Matla a khoheli a itseng asolids | Boemo ba lintho tsa nama | Boleng ba PH | Boholo bo tiileng(Mesh) |

| Mocheso (℃) | Pholoso eaLi-hads / solids | Likahare tsa metsi aKhutsoana ea sefahleho | Ho sebetsalihora / letsatsi | Bokaholimo / Letsatsi | Hore na mokelikelie mouoane kapa che |

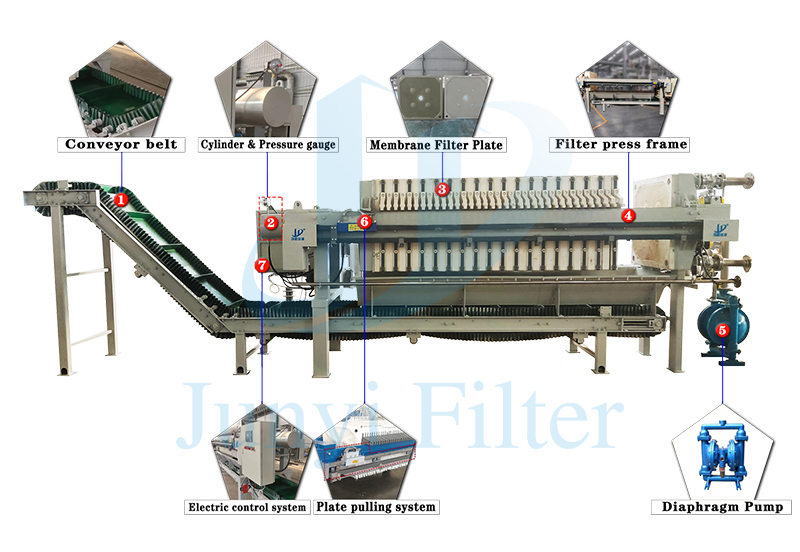

① Conveyor lebanta: Sesebelisoa se sebetsa sa sebaka sa mosebetsi se sa bonolo ho se etsa. Ke sesebelisoa se tšehetsang, se kentsoeng tlasa lipolanete tsa Filter tsa filthara ea Filter ho fetisa likuku tsa filthara, 'me li ka tsamaisa likhohola tsa basebetsi tse behiloeng, li fokotsa ho ba le matla a basebetsi.

② Sehatsetsi: Ka sistimi ea Hydraulic, silinda ea oli e ikarabella bakeng sa ho fetola matla a khatello ea metsi ka matla a motlakase kapa ho sisinyeha.

Khatello ea Hand: E bonts'a khatello ea ho hatella libaka tsa sethala sa silita ea oli.

Plate ea filter ea membrane ea polasetiki ea " Boholo ba mahareng (metsi kapa moea o hatelletsoeng, jj.) Bo hlahisoa ka phapusing ea khale le ho fokotsa likuku tsa filthara tsa likuku. Diaphragm ke karolo ea mantlha.

④ Filter Cress Beam: Mochine oa daephragm oa diaphragm o bokelletsoe le ho hlapanya ka lipolanete tsa q345b. Kamora ho thunya ha lebelo le phahameng haholo ho thunya le thibelo ea mashu, e fafatsoa ka bosholu ba bosholu ba koro ea khanyetso, 'me bokaholimo bo hahiloe ka likarolo tse tharo tsa pente e meraro.

⑤ Diaphragm Poump: qbk / QBK ea Doneumatic daephragm pompo ke pompo ea norvel e teng China hajoale. E ka pofatsa le ho monya lino tsohle tsa lino tse tahiloeng, joalo ka lino tse tahang, li phatlohang, lijalo tse tukang ka sekepeng sa oli tsa oli, le tanka ea nakoana. Ho phalla ha 'mele oa pompo ho entsoe ka tšepe ea tšepe, allohragm Mohloli, ka hlooho ea 7M, ho phahamisa 0-90m, le phallo ea 0,8-40 m3 / h, e ka fetoloang e le hantle.

Re ka boela ra ba le mefuta e meng ea ho fepa pompo ho latela lisebelisoa tse fapaneng tsa peō.

Sistimi ea poleiti e hula: Sisteme ea poleiti e ikemetseng e ikemetse, 'me basebelisi ba ka khetha hore na ba tla e kenya kapa che. E nka liketane tsa tšepe tse nang le steel le li-theipulator e se nang thuso.

Mokhoa oa taolo ea motlakase: E entsoe haholo ka lebaka la motlakase, likarolo tsa motlakase, mojali oa motlakase, e jj, ho laola litšila tsa litšila.

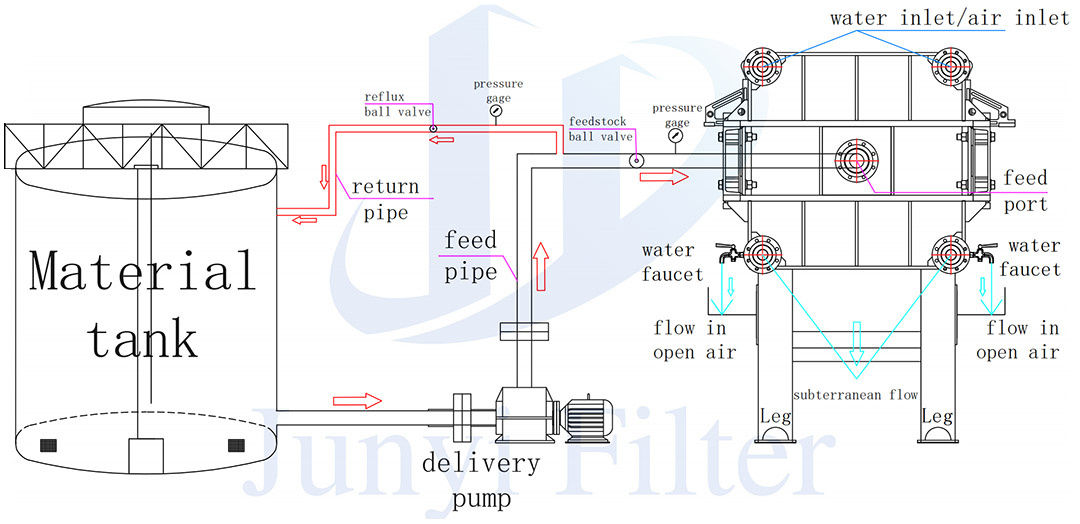

Ts'ebetso ea ho fepa

Indasteri ea ts'ebeliso

E sebelisoa haholo ts'ebetsong ea karohano e tiileng ea metsi, lik'hemik'hale, lijo tsa maoatle, ke joala ho kenella, ho ts'oaroa le tlhophiso tsa tikoloho.

Filter Press

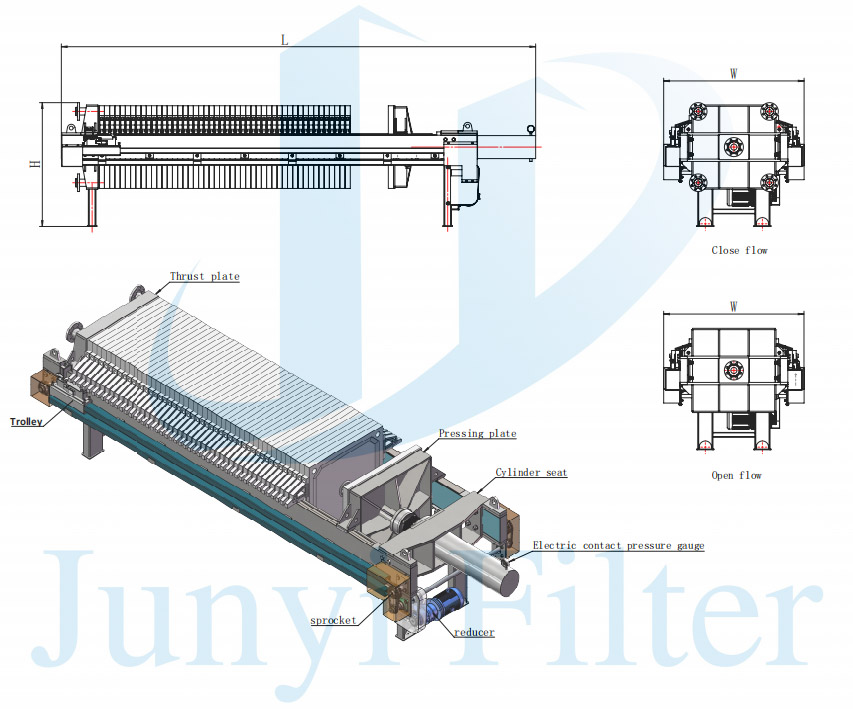

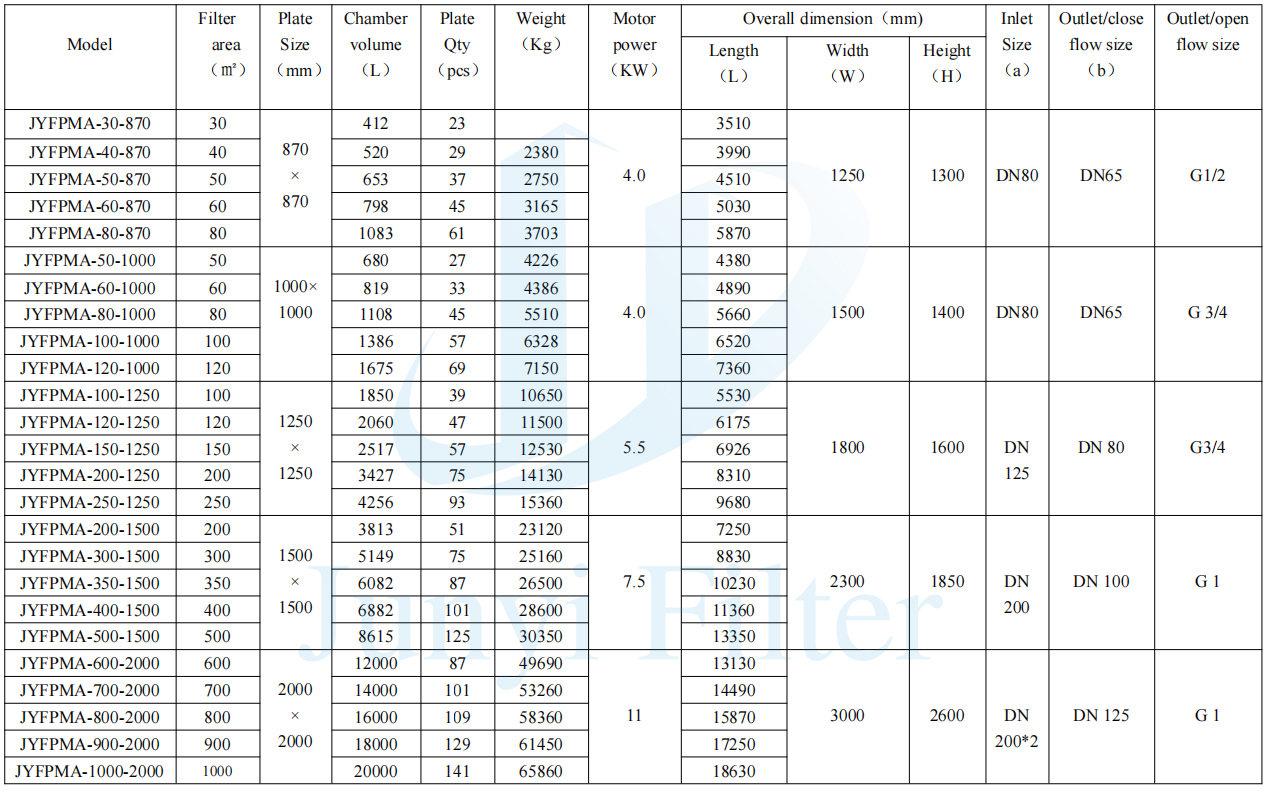

1. Sheba tataiso ea khetho ea lifilimi tsa filthara, Filter Pressview, litlhaloso le mehlala, khethamofuta oa mohlala le ho ts'ehetsa ho ea ka litlhoko.

Mohlala: Ekare hore hore na keke ea filthara e hlatsoe kapa che, hore na ea hlobolang e bulehile kapa e haufi,Hore na racks ke bo-cossunion - e thibelang kapa che, mokhoa oa ts'ebetso, jj., e tlameha ho hlalosoa hokonteraka.

2. Ho latela litlhoko tse ikhethang tsa bareki, k'hamphani ea rona e ka etsoa le ho hlahisamefuta e seng ea maemo kapa lihlahisoa tse hlophisitsoeng.

3. Litšoantšo tsa sehlahisoa tse fanoeng tokomaneng ena li bua ka eona feela. Tabeng ea liphetoho, ronae ke ke ea hlokomela tsebiso le tatellano ea 'nete.