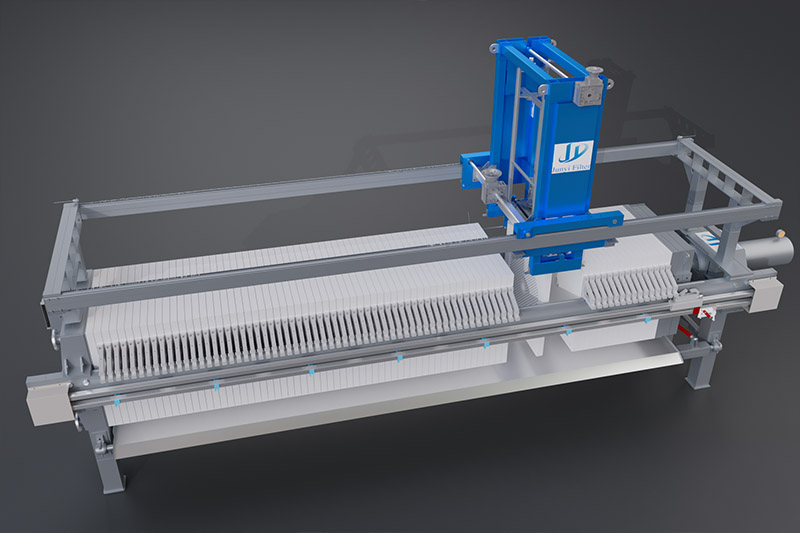

Sefahla sa diaphragm se nang le sesebelisoa sa ho hloekisa lesela

✧ Likarolo tsa Sehlahisoa

Lisebelisoa tse tsamaellanang tsa mochini oa "diaphragm": Sefate se tsamaisang lebanta, lesela le amohelang mokelikeli, sisteme ea ho hlatsoa lesela la lesela, sekoti sa polokelo ea seretse, jj.

A-1. Khatello ea ho hloekisa: 0.8Mpa; 1.0Mpa; 1.3Mpa; 1.6Mpa. (Ha ho boikhethelo)

A-2. Diaphragm e hatellang khatello ea kuku: 1.0Mpa; 1.3Mpa; 1.6Mpa. (Ha ho boikhethelo)

B, Filtration mocheso: 45 ℃ / mocheso kamoreng; 65-85℃/ mocheso o phahameng.(Ho ikhethela)

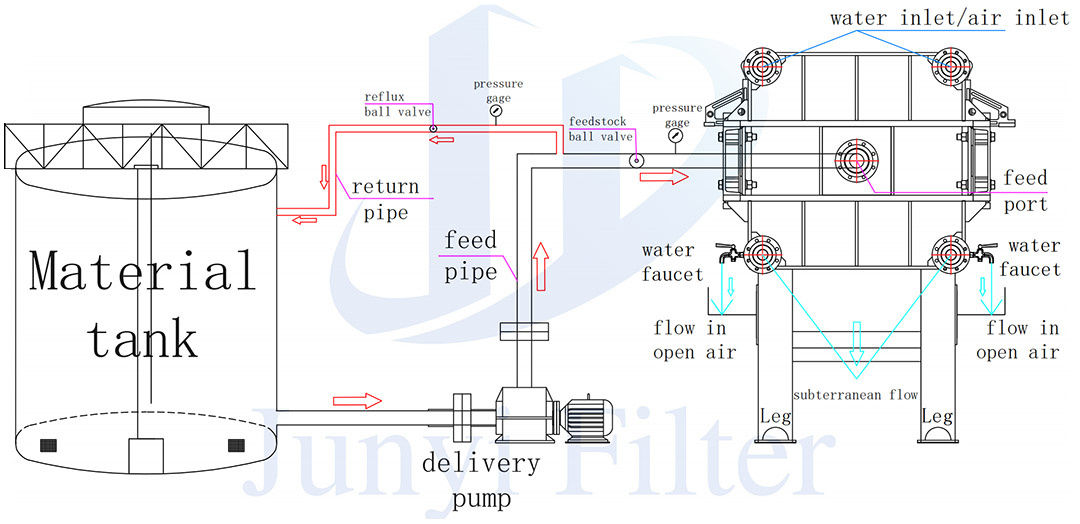

C-1. Mokhoa oa ho lahla - phallo e bulehileng: Lipompo li hloka ho kenngoa ka tlase ho lehlakore le letšehali le le letona la poleiti ka 'ngoe ea sefe, le sinki e ts'oanang. Phallo e bulehileng e sebelisoa bakeng sa maro a sa fumaneheng.

C-2. Mokhoa oa ho ntša metsi -e leng phallo e haufi: Tlas'a phepelo ea mochini oa mochini o hloekisang, ho na le liphaephe tse peli tse haufi tsa phallo, tse hokahaneng le tanka ea ho khutlisa metsi. Haeba mokelikeli o hloka ho khutlisoa, kapa haeba mokelikeli o fetoha, o nkha, o ka tuka ebile o phatloha, ho sebelisoa phallo e lefifi.

D-1. Khetho ea thepa ea lesela la sefa: PH ea mokelikeli e etsa qeto ea hore na lesela la sefe. PH1-5 ke lesela la filthara ea acidic polyester, PH8-14 ke lesela la filthara ea alkaline polypropylene. Mokelikeli oa viscous kapa o tiileng o khethoa ho khetha lesela la twill filthara, 'me mokelikeli o se nang viscous kapa o tiileng o khethoa lesela le hlakileng la filthara.

D-2. Khetho ea lesela la lesela la filthara: Mokelikeli o arotsoe, 'me ho khethoa nomoro e lumellanang ea mesh bakeng sa boholo bo fapaneng bo tiileng. Sefa lesela letlooeng la letlooeng la 100-1000 mesh. Phetolelo ea Micron ho ea ho letlooeng (1UM = 15,000 mesh---ka khopolo).

E.Rack holim'a phekolo: boleng ba PH bo sa nke lehlakore kapa bo fokolang ba acid; Bokaholimo ba foreime ea mochini oa mochini oa filthara bo chesoa ka lehlabathe pele, ebe bo fafatsoa ka pente ea primer le anti-corrosion. Boleng ba PH ke asiti e matla kapa alkaline e matla, bokaholimo ba foreimi ea mochini oa sefa e entsoe ka lehlabathe, e fafalitsoe ka primer, 'me bokaholimo bo phuthetsoe ka tšepe e sa hloekang kapa poleiti ea PP.

Ts'ebetso ea khatiso ea F.Diaphragm filter: Automatic Hydraulic Pressing; Hlatsoa likuku tse sefang, Ho hula ka ho iketsa Filter Plate; Filter Plate Vibrating Cake Discharge; Sistimi ea ho hlatsoa lesela ka ho iketsa. Ka kopo mpolelle ka mosa mesebetsi eo u e hlokang pele u odara.

Ho hlatsoa likuku tsa G.Filter: Ha lintho tse tiileng li hloka ho khutlisoa, kuku e sefang e na le asiti e matla kapa e alkaline; Ha kuku ea filthara e hloka ho hlatsuoa ka metsi, ka kopo romella lengolo-tsoibila ho botsa ka mokhoa oa ho hlatsoa.

Khetho ea pompo ea ho fepa ka mochine oa H.Filter: Karo-karolelano e tiileng-metsi, acidity, mocheso le litšobotsi tsa mokelikeli li fapane, kahoo ho hlokahala lipompo tsa phepelo tse fapaneng. Ka kopo, romella lengolo-tsoibila ho botsa.

I.Automatic lebanta conveyor: Lebanta la conveyor le kenngoa ka tlas'a poleiti ea mochine oa ho hloekisa, e sebelisetsoang ho tsamaisa kuku e khaotsoeng ka mor'a hore lipoleiti tsa filthara li huloe. Sesebelisoa sena se loketse morero o sa lokelang ho etsa fatše fatše. E ka isa kuku sebakeng se khethiloeng, e leng se tla fokotsa mosebetsi o mongata.

J.Automatic rotha tray: Terei ea ho rotha e kentsoe ka tlas'a poleiti ea mochini oa sefa. Nakong ea ts'ebetso ea ho hloekisa, li-trays tse peli tsa poleiti li boemong bo koetsoeng, bo ka lebisang mokelikeli o rothang nakong ea ho hloekisa le metsi a hlatsoang lesela ho ea ho mokelli oa metsi ka thōko. Ka mor'a ho hloekisa, li-tray tse peli li tla buloa ho ntša kuku.

K. The filthara tobetsa lesela metsi flushing system: E kentsoe ka holim'a lesela le leholo la mochine oa khatiso oa filthara, 'me e na le ts'ebetso e ikemetseng ea ho tsamaea,' me lesela le hloekisang le hlatsuoa ka metsi a phahameng (36.0Mpa) ka ho fetola valve. Ho na le mefuta e 'meli ea mekhoa ea ho hlatsoa: ho hlatsoa ka lehlakoreng le le leng le ho hlatsoa ka mahlakoreng a mabeli, moo ho hlatsoa ka mahlakoreng a mabeli ho nang le borashe bakeng sa ho hloekisa hantle. Ka mochine oa flap, metsi a hlatsoang a ka sebelisoa hape 'me a sebelisoa hape ka mor'a phekolo ho boloka mehloli; e kopantsoe le sistimi ea khatiso ea diaphragm, e ka fumana metsi a tlase; foreimi e kopaneng, sebopeho se kopaneng, ho bonolo ho qhaqha le ho tsamaisa.

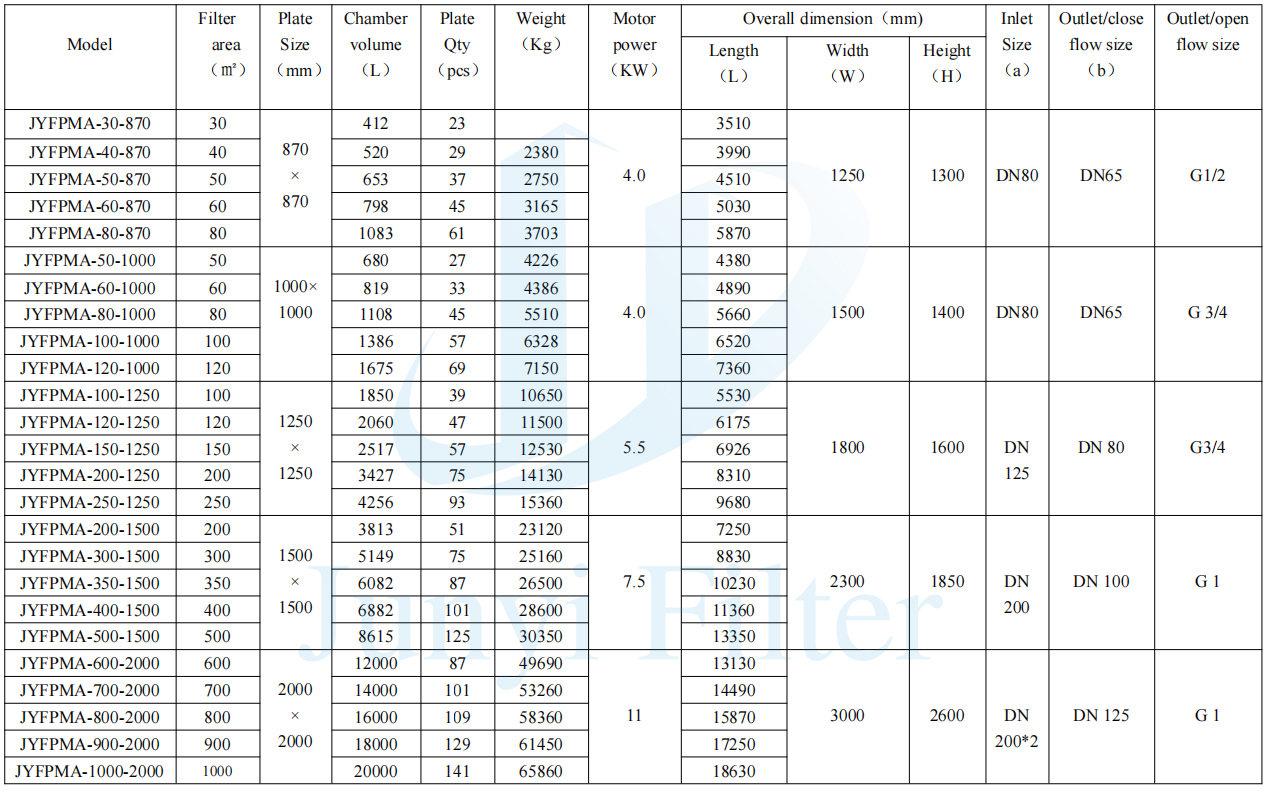

| Tataiso ea Mohlala oa Sesefa | |||||

| Lebitso la mokelikeli | Karolelano e tiileng-metsi(%) | Matla a khoheli a khethehileng atse tiileng | Boemo ba lintho tse bonahalang | PH boleng | Boholo bo tiileng(mesh) |

| Mocheso (℃) | Pholiso eamaro/dintho tse tiileng | Likahare tsa metsi tsakuku e sefang | Ho sebetsalihora/letsatsi | Bokhoni/letsatsi | Ebang ke mokelikelimouoane kapa che |

✧ Mokhoa oa ho fepa

✧ Liindasteri tsa Likopo

E sebelisoa haholo ts'ebetsong ea karohano ea mokelikeli o tiileng ka petroleum, lik'hemik'hale, dyestuff, metallurgy, pharmacy, lijo, ho hlatsoa mashala, letsoai le sa tloaelehang, joala, lik'hemik'hale, metallurgy, k'hemistri, indasteri e khanyang, mashala, lijo, masela, tšireletso ea tikoloho, matla le liindasteri tse ling.

✧ Sefa Litaelo tsa ho Odara

1. Sheba tataiso ea khetho ea mochini oa filthara, kakaretso ea tobetsa ea sefe, litlhaloso le mefuta, khethamohlala le lisebelisoa tse tšehetsang ho latela litlhoko.

Mohlala: Hore na kuku e hlatsuoa kapa che, hore na metsi a litšila a bulehile kapa a koetsoe,hore na rack ha e na kutu kapa che, mokhoa oa ts'ebetso, joalo-joalo, o tlameha ho hlalosoa hokonteraka.

2. Ho ea ka litlhoko tse khethehileng tsa bareki, k'hamphani ea rona e ka qapa le ho hlahisamefuta e sa tloaelehang kapa lihlahisoa tse ikhethileng.

3. Litšoantšo tsa sehlahisoa tse fanoeng tokomaneng ena ke tsa tšupiso feela. Tabeng ea liphetoho, ree ke ke ea fana ka tsebiso leha e le efe mme taelo ea sebele e tla ba teng.

✧ Drawing Of Automatic Filter Tobetsa ka Lesela Metsi Flushing System

✧ Tobetsa Sesefa sa Diaphragm ka ho iketsa

✧ Video