Automatic Filter Press Supplier

✧ Likarolo tsa Sehlahisoa

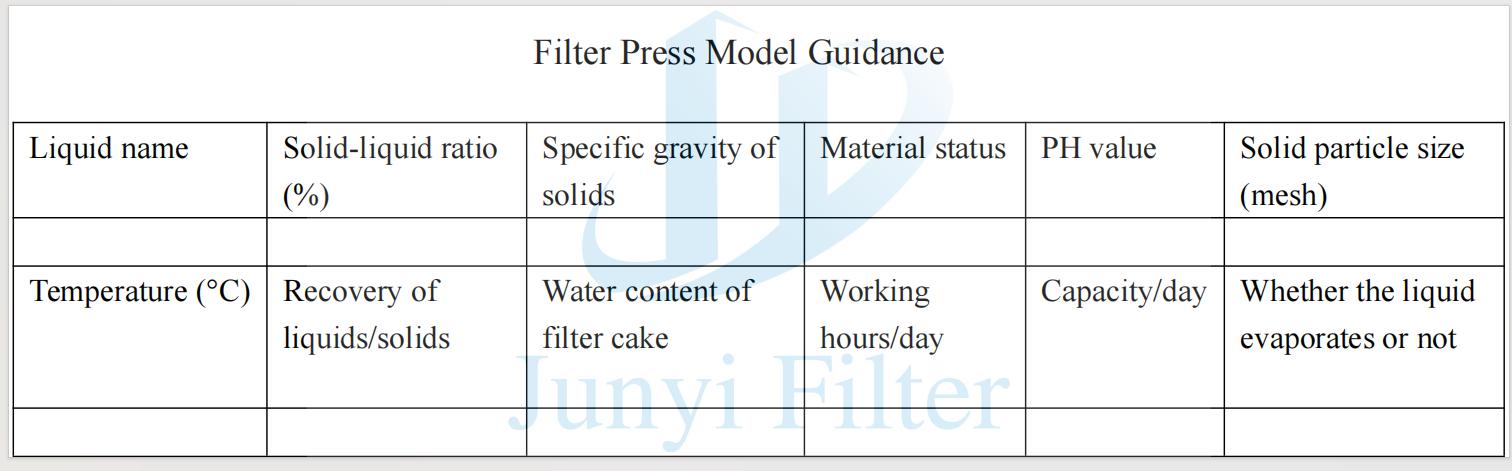

AKhatello ea ho sefa:0.6Mpa----1.0Mpa----1.3Mpa-----1.6mpa (bakeng sa khetho)

BMocheso oa ho hloekisa:45 ℃ / mocheso oa kamore; 80 ℃ / mocheso o phahameng; 100 ℃/ Mocheso o phahameng.Karo-karolelano ea lisebelisoa tse fapaneng tsa lipoleiti tse fapaneng tsa tlhahiso ea mocheso ha li tšoane, 'me botenya ba lipoleiti tsa filthara ha bo tšoane.

C-1Mokhoa oa ho lahla - phallo e bulehileng: Lipompo li hloka ho kenngoa ka tlas'a mahlakoreng a letšehali le a ka ho le letona a poleiti ka 'ngoe ea sefe, le sinki e ts'oanang. Phallo e bulehileng e sebelisoa bakeng sa maro a sa fumaneheng.

C-2Mokhoa oa ho ntša metsi - clahleheloaflow:Tlas'a phepelo ea mochini o hloekisang, ho na le liphaephe tse peli tse haufi tsa phallo e haufi, tse hokahaneng le tanka ea ho hlaphoheloa ea filtrate. Haeba mokelikeli o hloka ho khutlisoa, kapa haeba mokelikeli o fetoha, o nkha, o ka cha 'me o phatloha, ho phalla ho haufi ho molemo.

D-1Khetho ea thepa ea lesela la filthara: PH ea mokelikeli e etsa qeto ea thepa ea lesela la filthara. PH1-5 ke lesela la filthara ea acidic polyester, PH8-14 ke lesela la filthara ea alkaline polypropylene. Mokelikeli oa viscous kapa o tiileng o khethoa ho khetha lesela la twill filthara, 'me mokelikeli o se nang viscous kapa o tiileng o khethoa lesela le hlakileng la filthara.

D-2Khetho ea mesh ea lesela la filthara: Mokelikeli oa aroloa, 'me nomoro ea letlooeng e tsamaellanang e khethoa bakeng sa boholo bo fapaneng ba likaroloana tse tiileng. Sefa lesela letlooeng la letlooeng la 100-1000 mesh. Phetolelo ea Micron ho ea ho letlooeng (1UM = 15,000 mesh---ka khopolo).

E,Phekolo ea rack surface:Ha PH e na le boleng bo sa nkeng lehlakore kapa bo fokolang ba asiti, bokaholimo ba sefahla sa mochini oa sefa se ntšoa ka lehlabathe pele, ebe se fafatsoa ka pente e thibelang ho bola. Ha boleng ba PH e le asiti e matla kapa alkaline e matla, bokaholimo ba foreimi ea mochini oa sefa bo tšeloa ka lehlabathe, bo fafatsoa ka primer, 'me bo phuthetsoe ka tšepe e sa hloekang kapa poleiti ea PP.

FSefa ho hlatsoa likuku: Ha lintho tse tiileng li hloka ho khutlisoa, kuku e sefang e na le asiti e matla kapa e alkaline; Ha kuku ea filthara e hloka ho hlatsuoa ka metsi, ka kopo romella lengolo-tsoibila ho botsa ka mokhoa oa ho hlatsoa.

GKhetho ea pompo ea ho fepela ka filthara:Karo-karolelano ea metsi a tiileng, acidity, mocheso le litšobotsi tsa mokelikeli li fapane, kahoo ho hlokahala lipompo tse fapaneng tsa phepelo. Ka kopo, romella lengolo-tsoibila ho botsa.

✧ Mokhoa oa ho fepa

✧ Liindasteri tsa Likopo

E sebelisoa haholo ts'ebetsong ea karohano ea mokelikeli o tiileng ka petroleum, lik'hemik'hale, dyestuff, metallurgy, pharmacy, lijo, ho hlatsoa mashala, letsoai le sa tloaelehang, joala, lik'hemik'hale, metallurgy, k'hemistri, indasteri e khanyang, mashala, lijo, masela, tšireletso ea tikoloho, matla le liindasteri tse ling.

✧ Sefa Litaelo tsa ho Odara

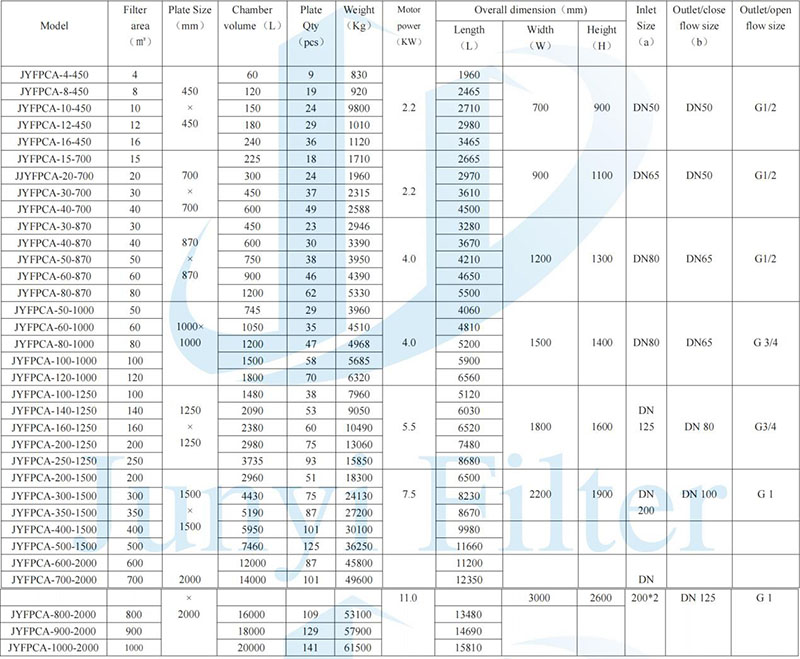

1. Sheba tataiso ea khetho ea mochini oa filthara, kakaretso ea tobetsa ea sefe, litlhaloso le mefuta, khethamohlala le lisebelisoa tse tšehetsang ho latela litlhoko.

Mohlala: Hore na kuku e sefang e hlatsoitsoe kapa che, ho sa tsotellehe hore na filtrate e butsoe (e bonoang phallo) kapa e koalehile (phallo e sa bonahaleng),hore na rack ha e na kutu kapa che, mokhoa oa ts'ebetso, joalo-joalo, o tlameha ho hlalosoa hokonteraka.

2. Ho ea ka litlhoko tse khethehileng tsa bareki, k'hamphani ea rona e ka qapa le ho hlahisamefuta e sa tloaelehang kapa lihlahisoa tse ikhethileng.

3. Litšoantšo tsa sehlahisoa tse fanoeng tokomaneng ena ke tsa tšupiso feela. Tabeng ea liphetoho, ree ke ke ea fana ka tsebiso leha e le efe mme taelo ea sebele e tla ba teng.

✧ Litlhokahalo tsa ts'ebeliso ea mochini oa sefahla

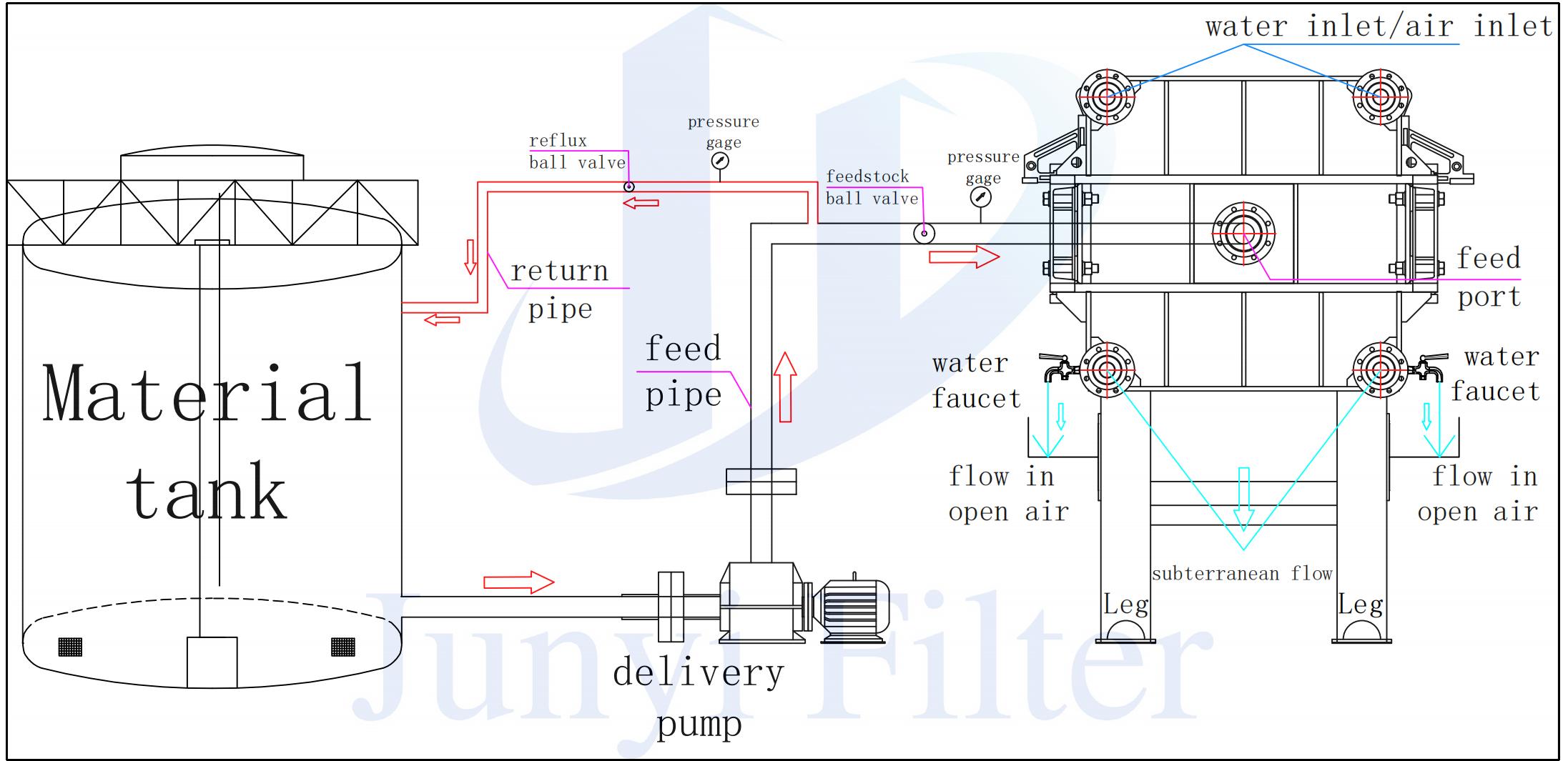

1. Ho ea ka litlhoko tsa ts'ebetso ea ho etsa khokahanyo ea liphaephe, le ho etsa tlhahlobo ea ho kena ha metsi, ho lemoha ho tiea ha moea oa pipeline;

2. Bakeng sa ho hokahanya ha motlakase oa ho kenya letsoho (mohato oa 3 + o sa nke lehlakore), ho molemo ho sebelisa mohala oa fatše bakeng sa khabinete ea taolo ea motlakase;

3. Khokahano pakeng tsa khabinete ea taolo le lisebelisoa tse potolohileng. Lithapo tse ling li hoketsoe. Li-terminals tsa line ea tlhahiso ea khabinete ea taolo li ngotsoe. Sheba setšoantšo sa potoloho ho hlahloba wiring le ho e hokahanya. Haeba ho na le ho lokoloha ho femeng e tsitsitseng, hatella hape;

4. Tlatsa seteishene sa hydraulic ka 46 # oli ea hydraulic, oli ea hydraulic e lokela ho bonoa fensetereng ea ho shebella tanka. Haeba mochine oa khatiso o sebetsa o sa khaotse bakeng sa lihora tse 240, tlosa kapa u sefa oli ea hydraulic;

5. Ho kenya mochine oa khatello ea cylinder. Sebelisa wrench ho qoba ho potoloha ka letsoho nakong ea ho kenya. Sebelisa selikalikoe sa O-ho hokahanya pakeng tsa tekanyo ea khatello le cylinder ea oli;

6. Lekhetlo la pele ha moqomo oa oli o matha, motlakase oa seteishene sa hydraulic o lokela ho potoloha ho ea ka nako (e bonts'itsoeng koloing). Ha moqomo oa oli o sutumelletsoa pele, setsi sa tekanyo ea khatello e lokela ho ntša moea, 'me moqomo oa oli o lokela ho sutumetsoa ka pele le ka morao (khatello e ka holimo ea tekanyo ea khatello ke 10Mpa) le moea o lokela ho lokolloa ka nako e le' ngoe;

7. Mochine oa filthara o sebetsa ka lekhetlo la pele, khetha boemo ba letsoho ba khabinete ea taolo ho tsamaisa mesebetsi e fapaneng ka ho latellana; Ka mor'a hore mesebetsi e be e tloaelehileng, u ka khetha boemo bo itekanetseng;

8. Ho kenngoa ha lesela la filthara. Nakong ea ts'ebetso ea teko ea mochine oa ho hloekisa, poleiti ea filthara e lokela ho hlomelloa ka lesela la filthara esale pele. Kenya lesela la sefe holim'a poleiti ea sefe ho etsa bonnete ba hore lesela le sefang le bataletse 'me ha ho na likhechana kapa tse fetang. Sututsa poleiti ea sefe ka letsoho ho netefatsa hore lesela le sefang le bataletse.

9. Nakong ea ts'ebetso ea mochini o hloekisang, haeba kotsi e hlaha, opareitara e tobetsa konopo ea ho emisa tšohanyetso kapa o hula thapo ea tšohanyetso;

✧Liphoso tse ka sehloohong le mekhoa ea ho rarolla mathata

| Ketsahalo ea phoso | Molao-motheo oa Phoso | Ho batle phoso |

| Lerata le matla kapa khatello e sa tsitsang tsamaisong ea hydraulic | 1, Pompo ea oli ha e na letho kapa phala e monyang oli e koetsoe. | Ho tlatsa tanka ea oli, rarolla ho lutla ha lipeipi tse monyang |

| 2, Sebaka se tiisang sa poleiti ea filthara se ts'oaroa ka misc. | Hloekisa ho tiisa libaka | |

| 3, Moea ka har'a potoloho ea oli | Felisa moea | |

| 4, Pompo ea oli e senyehile kapa e tsofetse | Ho fetola kapa ho lokisa | |

| 5, Belofo ea liphallelo ha e tsitsa | Ho fetola kapa ho lokisa | |

| 6. Ho sisinyeha ha phala | Ho tiisa kapa ho tiisa | |

| Khatello e sa lekaneng kapa e se nang letho tsamaisong ea hydraulic | 1, Tšenyo ea pompo ea oli | Ho fetola kapa ho lokisa |

| recalibration | |

| 3, Viscosity ea oli e tlase haholo | Ho fetola oli | |

| 4, Ho na le ho lutla tsamaisong ea pompo ea oli | Lokisa kamora tlhahlobo | |

| Khatello e sa lekaneng ea li-cylinder nakong ea khatello | 1, Valofo e senyehileng kapa e khomaretsoeng ka khatello e phahameng | Ho fetola kapa ho lokisa |

| 2, valve e senyehileng ea ho khutlisa | Ho fetola kapa ho lokisa | |

| 3, Setiiso se seholo sa piston se senyehileng | phetoho | |

| 4, tiiso e nyenyane ea piston "0" e senyehileng | phetoho | |

| 5, Pompo ea oli e senyehileng | Ho fetola kapa ho lokisa | |

| 6、Khatello e lokisitsoe ka phoso | nchafatsa | |

| Khatello e sa lekaneng ea li-cylinder ha u khutla | 1, Valofo e senyehileng kapa e khomaretsoeng ka khatello e tlase | Ho fetola kapa ho lokisa |

| 2, Setiiso se senyenyane sa piston se senyehileng | phetoho | |

| 3, tiiso e nyenyane ea piston "0" e senyehileng | phetoho | |

| Piston e hahabang | Moea ka har'a potoloho ea oli | Ho fetola kapa ho lokisa |

| Lerata le tebileng la phetiso | 1、Ho jara tšenyo | phetoho |

| 2. Ho otla kapa ho roala | Ho fetola kapa ho lokisa | |

| Ho lutla ho hoholo lipakeng tsa lipoleiti le liforeimi |

| phetoho |

| 2. Lithako tse holim'a ho tiisa | Hloekileng | |

| 3. Sefa lesela le nang le mameno, li-overlaps, joalo-joalo. | E tšoaneleha bakeng sa ho qeta kapa ho nkeloa sebaka | |

| 4. Matla a khatello a sa lekaneng | Keketseho e nepahetseng ea matla a khatello | |

| Letlapa le foreimi li robehile kapa li holofetse | 1, Khatello ea sefa e phahame haholo | fokotsa khatello |

| 2, Mocheso o phahameng oa thepa | Lithempereichara tse theoletsoeng ka nepo | |

| 3. Matla a khatello a phahame haholo | Fetola matla a khatello ka nepo | |

| 4. Ho sefa kapele haholo | Sekhahla sa ho sefa se fokotsehile | |

| 5, lesoba la phepelo le koetsoeng | Ho hloekisa lesoba la phepelo | |

| 6、 Ho emisa bohareng ba ho sefa | U se ke ua emisa bohareng ba filtration | |

| Sistimi ea ho nchafatsa e sebetsa khafetsa | 1, valve ea ho hlahloba li-hydraulic control ha e koetsoe ka thata | phetoho |

| 2. Ho lutla ka silindara | Ho nkela sebaka sa li-cylinder seals | |

| Ho hloleha ha li-valve tsa Hydraulic | Spool e khomaretsoe kapa e senyehile | Harola le ho hloekisa kapa ho fetola valve ea tataiso |

| Trolley ha e khone ho huleloa morao ka lebaka la tšusumetso ea morao le pele. | 1, Khatello ea potoloho ea oli e tlase ea oli | lokisa |

| 2, Khatello ea relay ea khatello e tlase | lokisa | |

| Ho hloleha ho latela mekhoa | Ho hlōleha ha karolo ea tsamaiso ea hydraulic, tsamaiso ea motlakase | Lokisa kapa u nke sebaka ka mokhoa oa matšoao ka mor'a tlhahlobo |

| Tšenyo ea diaphragm | 1, khatello ea moea e sa lekaneng | Khatello ea khatiso e fokotsehileng |

| 2、 Phepelo e sa lekaneng | Ho hatella ka mora ho tlatsa phaposi ka lintho tse bonahalang | |

| 3. Ntho esele e phunyeletse diaphragm. | ho tlosa taba tsa kantle | |

| Tšenyo e kobehang ho beam e kholo | 1, metheo e futsanehileng kapa e sa lekaneng | Ntlafatsa kapa etsa bocha |