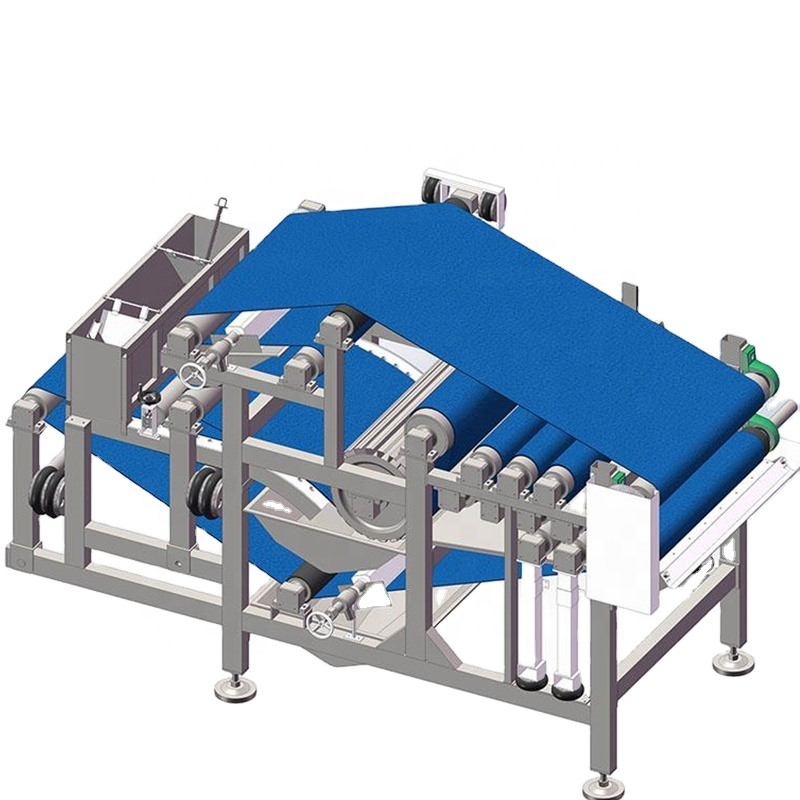

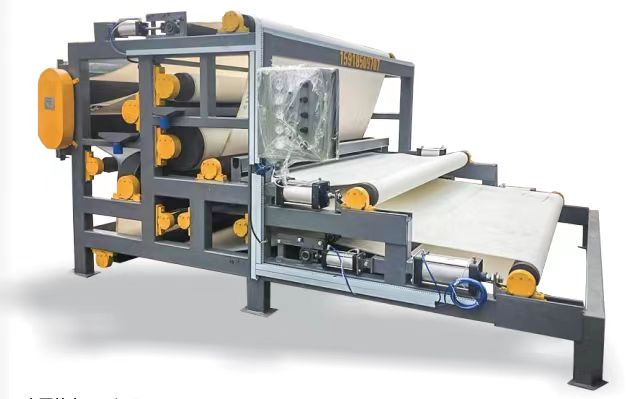

Sludge e thellisa mochine belt tobetsa filthara

Lihlahisoa tsa sehlahisoa

* Litefiso tse phahameng tsa ho phelisana le li-mongobo tse fokolang.

* Litsenyehelo tse tlase tsa ts'ebetso le tlhokomelo ea ho lokisa le tlhokomelo ka lebaka la moralo o sebetsang le o hlophisitsoeng.

* Khohlano e tlase e tsoetseng pele e tsoetseng pele ea 'Mala oa' Mala oa 'Mè oa Belt, Variants e ka fanoa kali-slide rails kapa li-roller li tšehetsoa ka mokhoa oa tšehetso.

* Tsamaiso e laoloang ea Belt e alimang e fella ka ho lokisa chelete e kenang.

* Makala a mangata a hlatsoa.

* Bophelo bo bolelele ba lebanta la 'Mm ka lebaka la khohlano e nyane ea tšehetso ea lebokose la moea.

* Ho fana ka tlhahiso ea likuku.

Indasteri ea ts'ebeliso

E sebelisoa haholo ts'ebetsong ea karohano e tiileng ea metsi, lik'hemik'hale, lijo tsa maoatle, ke joala ho kenella, ho ts'oaroa le tlhophiso tsa tikoloho.

Filter Press

1. Sheba tataiso ea khetho ea lifilimi tsa filthara, Filter Pressview, litlhaloso le mehlala, khethamofuta oa mohlala le ho ts'ehetsa ho ea ka litlhoko.

Mohlala: Ekare hore hore na keke ea filthara e hlatsoe kapa che, hore na ea hlobolang e bulehile kapa e haufi,Hore na racks ke bo-cossunion - e thibelang kapa che, mokhoa oa ts'ebetso, jj., e tlameha ho hlalosoa hokonteraka.

2. Ho latela litlhoko tse ikhethang tsa bareki, k'hamphani ea rona e ka etsoa le ho hlahisamefuta e seng ea maemo kapa lihlahisoa tse hlophisitsoeng.

3. Litšoantšo tsa sehlahisoa tse fanoeng tokomaneng ena li bua ka eona feela. Tabeng ea liphetoho, ronae ke ke ea hlokomela tsebiso le tatellano ea 'nete.

Liphoso tse ka sehloohong le mekhoa ea ho rarolla mathata

| Fault Phenomen | Molao-motheo oa Fault | Ho batle phoso |

| Lerata le leholo kapa khatello e sa tsitsang tsamaisong ea hydraulic | 1, pompo ea oli ha e na letho kapa phala ea koloi ea oli e koetsoe. | Tanka ea oli ea oli e theko e phahameng, rarolla bothata ba thapo ea Suction |

| 2, bokaholimo bo tiisitsoeng sa poleiti ea thetso bo tšoaroa ka Misc. | Bo-ramotse ba Hloekisa | |

| 3, Moea o potolohile | Moea o khathollang | |

| 4, pompo ea oli e senyehile kapa e apere | Sebelisa kapa ho lokisa | |

| 5, valve ea liphallelo ha e na thuso | Sebelisa kapa ho lokisa | |

| 6, pipe vibration | Ho tiisa kapa ho ts'oaroa | |

| E sa lekaneng kapa ha ho na khatello tsamaisong ea hydraulic | 1, tšenyo ea oli ea oli | Sebelisa kapa ho lokisa |

| Ho remal | |

| 3, pono ea oli e tlase haholo | Phetoho ea oli | |

| 4, ho na le leaky ka har'a sistimi ea oli | Lokisa Kamora Tlhahlobo | |

| Khatello e sa lekaneng ea mokhosisisi e sa lekaneng nakong ea khatello ea maikutlo | 1, e senyehileng kapa e tenang chefo ea liphallelo | Sebelisa kapa ho lokisa |

| 2, e senyehile Valve | Sebelisa kapa ho lokisa | |

| 3, e sentse tiiso ea kholo e kholo ea piston | Phetoho | |

| 4, e senyehileng e nyane ea piston "0" tiiso | Phetoho | |

| 5, pompo ea oli e senyehileng ea oli | Sebelisa kapa ho lokisa | |

| 6, khatello e fetotsoe ka nepo | pheta-pheta | |

| Khatello e sa lekaneng ea Cylinder Ha U Qalisa | 1, e senyehileng kapa e ts'oereng valve ea liphallelo tse tlase | Sebelisa kapa ho lokisa |

| 2, e senyehileng tiiso e nyane ea piston | Phetoho | |

| 3, e senyehileng ea piston e nyane "0" tiiso | Phetoho | |

| Piston o khasa | Moea ka potoloho ea oli | Sebelisa kapa ho lokisa |

| Molumo o Phethahetseng | 1, e behang tšenyo | Phetoho |

| 2, gear e otla kapa e apereng | Sebelisa kapa ho lokisa | |

| Ho lutla ka matla lipakeng tsa lipolanete le liforeimi |

| Phetoho |

| 2, maloanlatsana ka holimo | Hloekisa | |

| 3, lesela la filter le meralo, e fetang | Tšoaneleha bakeng sa ho qeta kapa ho khutlisa | |

| 4, Matla a qosomong a sa lekaneng | Keketseho e nepahetseng ea matla a qobelloang | |

| Poleiti le foreimi ba robehile kapa ba holofetse | 1, khatello ea limela e phahame haholo | theola khatello |

| 2, mocheso o phahameng oa lintho tse bonahalang | Ka mokhoa o nepahetseng mocheso | |

| 3, compression e matla haholo | Fetola khatello ea khatello ka nepo | |

| 4, Fapa haholo ka lebelo haholo | Sekhahla se fokotsehileng | |

| 5, e fepa ka lesoba | Ho hloekisa lesoba | |

| 6, ho emisa bohareng ba ho hloka fore | Se ke oa emisa bohareng ba filtation | |

| Sisteme ea phetisetso e sebetsang khafetsa | 1, hydraulic ea hydraulic ea ho hlahloba ha e koetsoe ka thata | Phetoho |

| 2, lutla ka silinda | Phetoho ea litiiso tsa silinda | |

| Hydraulic e nchafatsa ho hloleha ha Valve | Spool e khomarela kapa e senyehile | Ho hula le ho hlatsoa kapa ho khutlisa valve ea tataiso |

| Trolley e ke ke ea huloa ka morao ka lebaka la ts'ebetso ea morao. | 1, e tlase ea oli ea oli ea oli ea motor | Fetoha |

| 2, khatello ea maikutlo e lula e le tlase | Fetoha | |

| Ho sitoa ho latela mekhoa | Ho hloleha ha karolo ea sistimi ea hydraulic, sistimi ea motlakase | Lokisa kapa ho nkela ka mokhoa o hlakileng ka mor'a tlhahlobo |

| Tšenyo ea Diaphragm | 1, khatello e sa lekaneng ea moea | Ho fokotsoa khatello |

| 2, fepa e lekaneng | Ho tobetsa kamora ho tlatsa kamore e nang le thepa | |

| 3, ntho e tsoang naheng esele e phutha diaphragm. | Ho tlosoa ka ntle ho naha | |

| Ho betla tšenyo ea ho besa | 1, mafutsana kapa a sa lekanyetsoang | Ntlafatso kapa redo |